High Temperature Resistance Magnesium Alloy Billet For Extrusion with Customizable Size

Подробная информация о продукте:

| Место происхождения: | ХУНАН, Китай |

| Фирменное наименование: | high broad |

| Номер модели: | ЗК60 ВЕ43 МНЕ21 |

Оплата и доставка Условия:

| Количество мин заказа: | 100 |

|---|

|

Подробная информация |

|||

| Химический состав: | Мг Аль Зн Мн | Материал: | Металл магния |

|---|---|---|---|

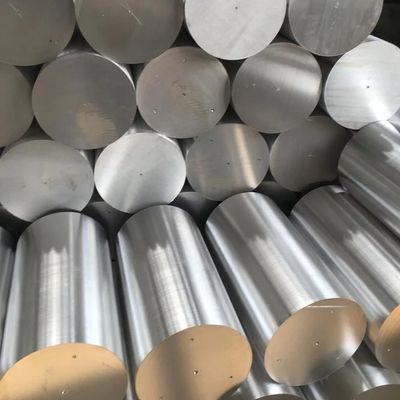

| Форма: | Стержневая стойка | Размер: | 60-150 мм |

| Диапазон диаметра: | 800 мм макс. | Длина диапазона: | 8500 мм макс. |

| Термальная обработка: | T5 | Предел прочности: | 306 МПа (МЫ43) |

| Доказательство стресса: | 234 МПа (WE43) | Удлинение: | 8% (МЫ43) |

| Содержание иттрия: | 3,7-5,5% | Содержание гадолиния: | 0-9,5% |

| содержание циркония: | 0,4-1,0% | Содержание цинка: | 1-1,5% (ЗЕ94) |

| Содержание неодима: | 1,5-2,5% | ||

| Выделить: | High Temperature Resistance Magnesium Alloy Billet,For Extrusion Magnesium Billet,Customizable Size Magnesium Alloy Bar |

||

Характер продукции

Magnesium alloy billets designed for extrusion applications, ideal for use in vibration, dust, corrosive, high temperature and other demanding environments.

- WE43

- WE54

- WE94

- AZ80A

- AZ91

- AZ31B

- ZM2

- ZM3

- ZM6

- ZK60

- MnE21

- Cast magnesium billets/bars

- Extruded magnesium billet/bars

- Rolling plate

- High strength magnesium alloys

Designed for use in vibration, dust, corrosive, high temperature and other demanding environments.

WE series magnesium alloys are magnesium based with Gadolinium, Yttrium, Zinc and Zirconium. These high strength casting alloys can be used in temperatures up to 300°C (572°F) and feature excellent mechanical properties and corrosion resistance.

Common applications include:

- Helicopter transmissions

- Power systems

- Aero-engines

- Sports cars

- Missiles

| Specification | Y | Gd | Nd | Zn | Zr |

|---|---|---|---|---|---|

| WE54 | 4.71-5.5 | 1.0-2.0 | 1.5-2.0 | - | 0.4-1.0 |

| WE43 | 3.7-4.3 | 0-1.9 | 2.0-2.5 | - | 0.4-1.0 |

| WE94 | 3.5-4.5 | 8.5-9.5 | - | 1-1.5 | 0.4-0.7 |

| Specification | Thermal Treatment Status | 0.25% Proof Stress (MPa) | Tensile Strength (MPa) | Elongation % |

|---|---|---|---|---|

| WE43 | T5 | 234 | 306 | 8 |

| WE54 | T5 | 205 | 280 | 4 |

| WE94 | T5 | 370 | 450 | 6 |

Suitable for extruding, rolling, and forging processes.

- Complies with GB/T19078-2003 and ASTM standards

- Available shapes: round, D shaped ingots, round bars and plate

- Dimensions: Diameter up to 800mm, Length up to 8500mm

Pallets

3-20 days after confirming order. Exact delivery date depends on production season and order quantity.

We have been producing various master alloys in China for over 10 years. Our product range includes:

Magnesium Yttrium (MgY25/30), Magnesium Manganese (MgMn3/5/10), Magnesium Calcium (MgCa15/20), Magnesium Cerium (MgCe20/25/30), Magnesium Neodymium (MgNd20/25/30), Magnesium Scandium (MgSc2/5/10/30), Magnesium Gadolinium (MgGd20/25/30), Magnesium Strontium (MgSr10/20), Magnesium Lanthanum (MgLa20/25/30), Magnesium Zirconium (MgZr25/30), Magnesium Erbium (MgEr20), Magnesium Aluminum (MgAl50/68), Magnesium Copper (MgCu15), Magnesium Lithium (MgLi10), Magnesium Silicon (MgSi3), Magnesium Barium (MgBa20), Nickel Magnesium (NiMg), and more.

ZK60, ZM2, ZM3, ZM6, ZM21, ZM31, WE43, WE57, WE94, MnE21, and others.

Aluminum Zirconium (AlZr), Aluminum Vanadium (AlV), Aluminum Ytterium (AlY), Aluminum Zinc (AlZn), Aluminum Titanium (AlTi), Aluminum Boron (AlB), Aluminum Manganese (AlMn), Aluminum Erbium (AlEr), Aluminum Lanthanium (AlLa), Aluminum Cerium (AlCe), Aluminum Iron (AlFe), Aluminum Scandium (AlSc), Aluminum Strontium (AlSr), Aluminum Cobalt (AlCo), Aluminum Chromium (AlCr), Aluminum Monium (AlMo), Aluminum Nickel (AlNi), and others.

Y ingot/granules, DyFe ingot, and more.

Our strong technical team can supply customized alloys according to customer requirements. Contact us for ICP machine test results and additional information.